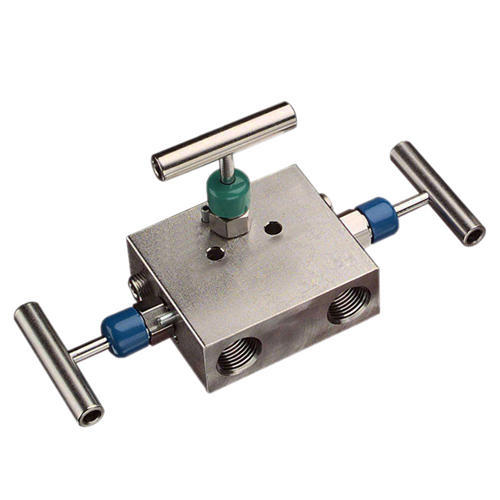

HASTELLOY 3 WAY MANIFOLD VALVE

HASTEALLOYS 3 WAY MANIFOLD VALVE MANUFACTURER

The Apexia Metal Is Provide HASTELLOY 3-WAY MANIFOLD VALVE

Elite Instrumentation Hastelloy C276 valves have better clogging than different acids. For example. Hastelloy C276 ball valves can resist acids such as sulfuric, hydrochloric. hydrofluoric, nitric, and corrosive chromic. The Hastelloy valve even has great opposition from confined consumption.

Hastelloy C276 Instrumentation Valve

Size: 1/2 “to 4” (DN25-DN200)

Chain: NPT PT BSPP G

Association: Welded, Plug, Fixed, Flanged, Threaded

Pressure factor class: PN10 / 16

Hastelloy Instrumentation Valves. Hastelloy Instrument Manifold Valves, Hastelloy Instrument Monoflange Valves. Hastelloy ASTM A494 Instrumentation Valve. Hastelloy Alloy Instrumentation Valves, Hastelloy Instrumentation Ball Valves Suppliers

Hastelloy cryogenic globe valves. Hastelloy ANSI B16.10 instrumentation valves. alloy double block and bleed (DBB) valve, Hastelloy manifold valve. Hastelloy safety valve, ASME SA 494 alloy metering valves. alloy single flange valves Nickel, Hastelloy Integral Bonnet Instrument Needle Valves. Alloy Industrial Instrumentation Valves Manufacturer

HASTEALLOYS 3WAY MANIFOLD VALVE MANUFACTURER IN INDIA

The articles that we manufacture are used in various uses by companies. for their different purposes. Modern applications for Hastelloy instrumentation valves are offshore oil drilling. chemical equipment, seawater equipment, petrochemicals, gas handling. pulp and paper industries, heat exchangers, condensers, and power generation industries. Energy. These are used in numerous companies for their opposition to high temperatures.

Also, we give distinctive test statements about the things we make. These statements are given according to EN 10204 3.1. The test statements we provide are the third-party inspection report. the staple certificate, the 100% X-ray test report, and other standard authentications.

The Hastelloy instrumentation valve package is completed with caution. and safety and we make sure all reports are incorporated. Hastelloy Instrumentation Valves are tested for quality reasons. and distinctive quality tests are performed, for example, IGC. and PMI tests, hardness tests. micro and macro tests, chemical analysis, and mechanical tests.

HASTEALLOYS 3 WAY MANIFOLD VALVE instrumentation Valves

Standard: ASTM A494 / SA494, ASME B16.10, ASME B16.5, ASME B16.25, ASME B16.34

Temperature rating: up to 400 ° C

End connection: screwed (NPT / BSPP / BSPT)

Nominal pressure factor: up to 6000 psi (413 bar).

Size range: ¼ “to 1”

HASTEALLOYS 3 WAY MANIFOLD VALVE Types

Instrument Solenoid Valve Manifold

Needle Valves for Hastelloy Integral Bonnet Instruments

Nickel Alloy Two Piece Instrument Ball Valves

Trunnion Ball Valves for Hastelloy Instruments

ANSI B16.10 Hastelloy DBB Valve

Exporter of amalgam metering valves

HASTELLOY 3 WAY MANIFOLD VALVE Instrumentation Valve Manifold

Hastelloy Instrumentation Valves

Hastelloy Bellows Fixed Valves

Hastelloy Fluid Line Shutoff Valves

Hastelloy Alloy Cryogenic Safety Relief Valve Supplier

Hastelloy O-ring seat

Hastelloy 3-way manifold valves

Amalgam Rising Plug Valves

ASME SA 494 Hastelloy Inline Gauge Isolation Valves

Push-in gauge isolating valve for reading Hastelloy online

Hastelloy Metering Valves

Hastelloy non-return check valve manufacturer

Hastelloy Alloy Mini Needle Valves

HASTEALLOYS 3 WAY MANIFOLD VALVE SUPPLIER

Hastelloy Pendulum Valve Manifold

Instrumentation Valves Shareholder

ASTM A494 Hastelloy Wellhead Bleed and Gauge Valve

Amalgam Sequence Control Valves

ANSI Hastelloy Fluid Control Ball Float Valve

Hastelloy Instrumentation Valve Manufacturers Assembly Standards

ASME B16.10 shows the maximum allowable pressure. for a fabric depending on the element being evaluated. and therefore the interaction temperature (the higher the temperature. the lower the pressure factor at a given rating). Hastelloy Two-Piece Instrument Valve, Tall Valve for Hastelloy Instruments. Trunnion Valve for Hastelloy Instruments. Alloy Trunnion Double Square Drain Ball Valves. Hastelloy Diaphragm Check Valves. Hastelloy Angle Instrument Globe Valves. Valve Bolt-On Bonnet Instrument Gate Valves, Double Block Instrument Bleed Valves. Hastelloy Monoflange Butterfly Valves

HASTEALLOYS 3 WAY MANIFOLD VALVE SUPPLIER IN INDIA

Instrumentation valve applications

3-Way Bypass Port Valves – Series D 5. Three-way ball valve with diverter port; Material of body, ball. stem and ends shall be 316 hardened steel, Hastelloy C-276, Hastelloy C-22, or other. Valve will be a three-piece plan. Seats and seals will be TFM®-PTFE material. and will provide a bubble-tight seal both upstream and downstream and will be mobile for in-line wear.

Body fasteners and nuts shall be 18-8 treated steel. The highest working voltage is 720 psig and full vacuum. State the design of the PBM sequence. To present mechanization and controls, see the segment “Robotization and controls”.

Materials:

Reinforced steel

316 S / S meets ASTM A 351-CF8M or A479, S31600

316L S / S complies with ASTM A 351-CF3M or A479, S31603

It is remarkably impervious to erosion in acidic. and essential conditions and does not sting without a problem.

It can be cleaned with a deep mirror finish for easy cleaning.

The welding accessories have a carbon content of <.03% to figure with welding. steel, A216-WCB

This flexible material handles somewhat destructive media.

Bronze, Alloy 922

Great protection against seawater conditions and great opposition to steam. Also reasonable for freezing temperature applications.

HASTELLOYS 3 WAY MANIFOLD VALVE

Generally, excellent consumption is decreasing and slightly oxidizing conditions. Excellent protection against confined assaults and really

great protection against stress and breakage of consumption. CW-12MW composite in cast structure.

Others

Additional materials are accessible. including alloy 20, bronze, duplex stainless steels, Hastelloy, titanium, and

Inconel®

HASTELLOYS 3 WAY MANIFOLD VALVE Industrial Valves

Hastelloy Alloy C22 Ball Valves. Hastelloy C22 Gate Valve | Hastelloy C22 Pulp Valves Distributor. Hastelloy Alloy C22 Plug Valves | Hastelloy C22 Globe Valves. C22 Hastelloy Needle Valves | Hastelloy C22 Butterfly Valves. Hastelloy Alloy C22 Manifold Valves shareholder. Hastelloy Alloy C22 Diaphragm Valve | Hastelloy C22 Jacketed Valves. Sight Glass Hastelloy C22 – Flow Indicating Valves

HASTEALLOYS 3 WAY MANIFOLD VALVE

Hastelloy Alloy 2.4602 Safety Safety Valve. Hastelloy N06022 Bleed Valves | Hastelloy 2.4602 Forged Steel Valve Manifold. UNS N06022 Flush Bottom Valves. DIN 2.4602 steel check valves | Hastelloy ANSI B16.10 Double Plate Check Valves. Hastelloy N06022 Automatic Control Valves. Hastelloy C22 Pneumatic Control Valves. Hastelloy C22 Alloy Check Valves (NRV) | Hastelloy. C22 Single and Double Block Bleed Valves

Using the 3-valve complex

In ordinary activity, the “separate” valves are open. while the “adjusting” valve is closed.

This gives you a differential pressure factor by examining. the pressure factor measurement or transmitter. To zero the instrument, first, close the downstream “trip” valve. then at that time open the “level” valve and change the zero setting on the instrument.

3 way

Immediate or distant designs

Two decoupling valves with a good outlet valve

Where necessary, a drain valve activity is additionally included.

Valve body materials

2-way complex hardened steel

The material of our standard complex valves is mild steel. However, it might be necessary to use complex valves under scandalous conditions. For exceptional applications. these collectors are accessible to manufacture in combinations such as Inconel. Incoloy, Hastelloy, Titanium, and Monel.

the presence of carbon in low quantity gives better welding qualities. to maintain a higher consumption obstruction in the structure “as welded”. The grade’s mechanical properties, for example, incredible flexibility, yield strength, high burst properties. and high elongation helps the valve to effectively withstand hot conditions. From now on, Hastelloy C276 Manifold Valves are useful in extreme conditions. due to their amazing features mentioned above.

About

We are one of the leading manufacturers of optimum quality Pipes & Pipe Fittings. Their high tensile strength, seamless finish and resistance to corrosion, make these pipes highly demanded.

Register Office

Contact

(+91) 9167472806

apexiametal@gmail.com

export.apexia@gmail.com

Follow

Copyright 2021 © Apexia Metal – All Rights Reserved || Developed & Maintained by Adsense Networks