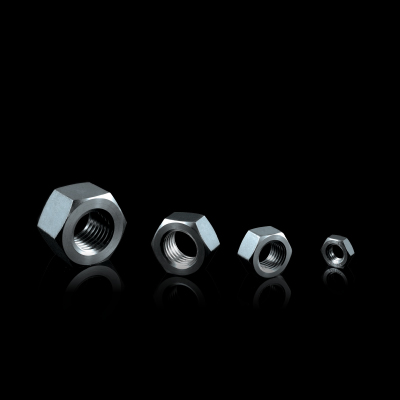

MONEL HEX NUT

MONEL HEX NUT MANUFACTURER

The Apexia Metal Is Supplies A Full Range Of Monel 400 Bolts, MONEL HEX NUT, Monel 400 Nuts, Monel 400 Screws Suppliers

The benefits of using 2.4360 (alloy 400) Bolts include their high strength. and excellent corrosion resistance. The properties of the ASTM F467 400 Monel are retained in a wide range of acidic. and alkaline environments. Alloy 400 Bolts are well suited for applications in reducing conditions.

Monel 400 has good ductility and thermal conductivity. Typically, Alloy 400 Fasteners finds application in chemicals. and hydrocarbon processing, marine engineering, heat exchangers, valves, and pumps. This is because of the MONEL HEX NUT. and Nuts are resistant to deterioration in both chemicals. as well as marine environments. Mostly, Monel 400 Socket Head Cap Screws are used in alkylation units. specifically in the reacting section. where the fasteners are in contact with concentrated hydrofluoric acid.

Monel 400 Washers contain a high percentage of metals. nickel and copper in their alloy. Although the MONEL HEX NUT is considered to be a very useful alloy. its cost is about 5 to 10 times more as compared to either plain copper or ordinary nickel. Therefore, its cost-ineffectiveness is the reason. why Monel 400 Screws aren’t used in most applications. Monel 400 is only used in those applications or operations. where no other metal or alloy could act as its substitute. For instance, Monel 400 Hex Bolt is one of those few alloys. that can retain its high tensile strength even in sub-zero temperatures. Hence, the Monel 400 Bolts are used in cases like this.

While the Monel 400 Nuts can be machined using conventional techniques as used for iron alloys. it is very difficult to machine this alloy as it tends to work harden during. this process. Alloy UNS N04400 Bolts can only be hardened by cold working with the application. of mechanical stress with soft die materials to change the shape of the alloy.

MONEL HEX NUT MANUFACTURER IN INDIA

Although the Monel 400 Fasteners are known to be resistant to corrosion towards many compounds. Monel 400, cannot withstand nitrous acid, nitric oxide, sulfur dioxide, and hypochlorites. Hence, Monel 400 must not be used in environments. where it would be exposed to those chemicals. Another disadvantage is that. Monel 400 tends to be susceptible to galvanic corrosion. which means that aluminum, zinc. or iron fasteners used along with Monel 400 can quickly corrode.

Compared to most stainless steel alloy grades, the cost of monel nuts. and bolts are much more expensive. Hence, the use of any component of this alloy is suggested by monel fasteners suppliers. to be used only when the use of stainless steel is not feasible. Because of the high contents of both nickel. and copper, the material is highly ductile and so it is easier to produce threads on a monel threaded rod.

the mechanical properties are known to be so good. that various industries purchase them from monel bolts suppliers. The alloy’s resistance to marine water is another area that attracts engineers. Even at elevated temperatures. the Monel Fasteners demonstrate resistance to both steam as well as to seawater. and brine. Rapid flowing seawater adds additional stresses to alloys. Not only do they have a high concentration of salt. but the flow of water exerts external pressure on the monel stud bolts.

a conventional stainless steel alloy like grade 304 would fail. But since the alloy offers a combination of high strength. and toughness, the monel bolts & nuts function well in rapid-flowing seawater. The combination of copper. and nickel added in the monel lock nuts permits its use at even cryogenic temperatures.

Monel 400 Nut Fastener Benefits

Monel NiCu 400 nuts provide a wide range of significant advantages. Monel nickel-copper 400 nuts provide the stability. and resilience needed to complete jobs. that regularly require the use of a fastener that can handle harsh environmental conditions. Other benefits related to Monel UNS N04400 fastener nuts include:

Ultra-tight threads

Increased safety, reliability, and economy

Extreme corrosion resistance

Advanced weight reduction

Monel 500 vs Monel 400 Nuts

MONEL HEX NUT SUPPLIER

Fundamentally, Monel 500 is an age-hardened version of Monel 400. which means that Monel 500 is more corrosion resistant and harder than Monel 400. Monel 500 is ideal for marine applications. where the hex bolt will be integrated with salt water consistently.

Conversely, Monel 400 maintains its toughness. and high strength over a wide temperature range. and is resistant to many corrosive environments. but is not used in as high of corrosive environments as Monel 500. However, Monel 400 is still considered one of the best ultra-strong. and corrosion-resistant nickel-copper alloys available.

Monel 400 Nut Fastener Material Qualities

Monel UNS N04400 nuts are manufactured from premium Monel 400 alloy metal materials. These materials consist mostly of nickel and copper. with varying amounts of iron, manganese, carbon, sulfur, and silicon. Monel 400 ASTM f467 nuts provide superior strength. while maintaining an extreme resistance to deterioration. Monel 400 nuts will also maintain their strength in sub-zero conditions. which allows them to be used in extreme environments. Some of the added material advantages of Monel 400 include:

MONEL HEX NUT SUPPLIER IN INDIA

Low corrosion rates

Excellent resistance to chloride-ion stress cracking

Good mechanical properties

Useable temperature range of sub-zero to 1,000° F

Exceptional resistance to hydrofluoric acid

Types of Monel 400/K500 Nuts

Monel Alloy 400/K500 Nuts

Monel 400/K500 T-Slot Nut

Monel 400/K500 Thin Nuts

Monel 400/K500 Wing Nuts

Monel 400/K500 Nylon Lock Nut

Monel 400/K500 Cap Nuts

Monel 400/K500 Square Nuts

Monel 400/K500 Coupling Nuts

Monel 400/K500 Hex Jam Nuts

Monel Alloy 400/K500 T-Nuts

Monel 400/K500 Auto Lock Nuts

Monel 400/K500 2-H Heavy Hex Nut

Monel 400/K500 Miscellaneous Nut

Monel 400/K500 Nylon Insert Lock Nuts

Monel 400/K500 Serrated Flange Nuts

Monel 400/K500 Hexagonal Nuts

Monel 400/K500 Panel Nuts

Monel 400/K500 Flex Lock Nuts

Monel 400/K500 Pin Lock Nuts

Monel 400/K500 Lug Nuts

Monel Alloy 400/K500 Eye Nuts

Monel 400/K500 High Tensile Nuts

Monel 400/K500 Cage Nuts

Monel 400/K500 Dome Nuts

Monel 400/K500 Knurled Nuts

Monel 400/K500 Keps-K Lock Nuts

Monel 400/K500 Machine Hex Nut

Monel 400/K500 Slotted Nuts

Monel 400/K500 Knurled Nuts

Monel 400/K500 Hex Jam Nuts

Monel 400/K500 Lifting Eye Nuts

Monel 400/K500 Sleeve Nuts

Monel 400/K500 Imperial Nuts

Monel 400/K500 Rivet Nuts

Monel 400/K500 Castle Nuts

Monel 400/K500 Weld Nuts

Monel 400/K500 Cage Nuts

Monel 400/K500 ACME Nuts

Monel 400/K500 High Nuts

About

We are one of the leading manufacturers of optimum quality Pipes & Pipe Fittings. Their high tensile strength, seamless finish and resistance to corrosion, make these pipes highly demanded.

Register Office

Contact

(+91) 9167472806

apexiametal@gmail.com

export.apexia@gmail.com

Follow

Copyright 2021 © Apexia Metal – All Rights Reserved || Developed & Maintained by Adsense Networks