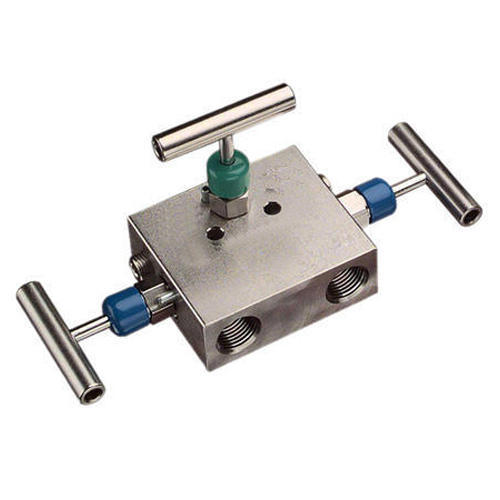

Stainless Steel 3 Way Manifold Valve

Stainless Steel 3 Way Manifold Valve Manufacture

The Apexia Metal Is Provide Instrumentation valves are one of the classes of valves accessible within the company. These valves are valuable for controlling. the liquid section during the pipeline or a line. It is a programmed device that controls the presence of liquid in any of the bearings. During a detour, they act as a control device for liquids such as fluids or gases. they are used within the pipeline framework and control gaps in them. the opening and closing are carried out through the valves.

Each valve decreases the pressure factor deficiency for the liquid inlet. They are also used in regions where the only liquid flow direction is needed. Typical applications incorporate blower or siphon release lines. Here you usually like the check valve. Other normal types of instrumentation valve are the world valve. valve, butterfly, gate, stomach, and adjusting valve. The inlet instrumentation valve offers complete opening or closing of gaps. they do not allow any misfortune of the liquid pressure factor. The connecting valve is generally called. a fast-acting valve because of its operation.

between the comforter and the valve, there is a stomach. so it is considered a stomach valve that ensures that there is no contact between these parts. The vast majority of petrochemical companies. use a valve due to its round depression and tiny sizes. It gives a situation close to the valve. However, when a fully closed position is not required, a globe valve is used. They are known for their seating capacity. The plate and the seat do not have contact so the consumption is absurd due to the liquid section.

Stainless Steel 3 Way Manifold Valve Manufacture in India

The butterfly INSTRUMENTATION VALVE has a circle. whose transverse distance is equal to the width of the valve body. Likewise, he stays away from the contact of the circle and the body. This ensures that there is no dirt during opening and closing. The check valve prevents further progression of the liquid. The Stainless Steel 3 Way Manifold Valve is normal in the compound. pipeline, design, petrochemical, gas, and oil plants.

Instrumentation Valves Specification

Standards API600, BS1414, ASME B16.34

Face to face ANSI B16.10

End connection Raised face, ring joint, undrilled, butt weld ANSI B16.25, ANSI B16.5, ASME B16.47 Series An or B

Stainless Steel 3 Way Manifold Valve

Stainless Steel 3 Way Manifold Valve for instrumentation in nickel alloys. Inconel. Incoloy, steel, Monel, etc. The offered 3-way manifold valve for instrumentation is created. using an unmatched nature of the hardware. Gautam Steel Proficient in 3-way Instrumentation Manifold Valve quality assistance. timely transportation and customer-centric approach. Backed by a group of professionals. we are busy offering a powerful quality scope of 3-way Instrumentation Manifold Valve.

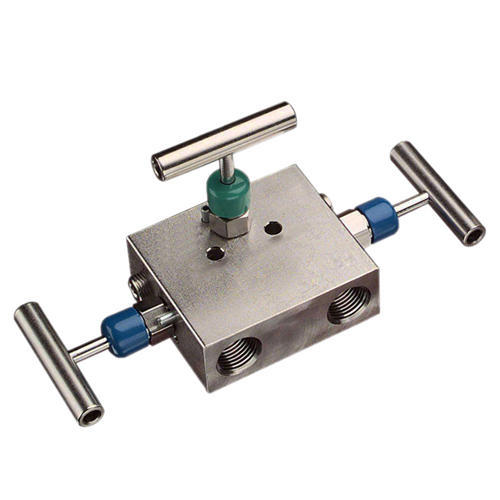

Instrumentation 3-way manifold valve specification

Kind:

3-way manifold valves

Stainless Steel 3 Way Manifold Valve Supplier

Work pressure:

6000 psi and better

Standard:

Planned and manufactured to regulate API / BS / DIN STANDARD

Final connections:

¼ “and ½” Associations with BSP, NPT, BSPT

Organ seat:

Standard P.T.F.E

Maximum temperature:

– 20 degrees C to +230 degrees C are based on various materials

Material:

SS316, SS304, CS, Hastelloy. Monel then in

Activity:

Pneumatically controlled: smooth, easy, low torque, long life

Quality:

The best quality in visual, materials. dimensional accuracy, operation, leak adjustment at that time

Application Industries:

Refineries, liquid petroleum gas handling plants. synthetic petroleum plants. structures difficult to cut due to strong substance dust, rust, dirt and then in

Tests:

• Each valve is 100% tested to ensure leakage is tight on the housing, seat, and gland.

Reflexes:

• Our complex valves are made up of 1/2 “NPT (F) connections.

• Pipe-to-column or rib-to-rib associations are provided.

• One leveling valve, two square valves, and one pair of 1/4 “NPT (F) cleaning valves.

• To cope with high temperature and press factor, we use Grafoil to press at 10,000 F and 6000 PSI pressure.

Stainless Steel 3 Way Manifold Valve Supplier in India

Instrumentation valves are one of the classes of valves accessible within the company. These valves are valuable for controlling the section of liquid during the channel or a line. it is a programmed gadget that controls the presence of liquid in any of the headers. During a detour, they act as a steering device for liquids such as fluids or gases. They are used in the framework of the pipeline and control the gaps in them. the opening and closing are carried out through the valves.

Each valve decreases the pressure factor deficiency for the liquid section. They are also used in regions where the only liquid flow direction is needed. Typical applications incorporate blower or siphon release lines. Here the check valve is the one I like the most. Other normal types of instrumentation valve are the world valve. valve, butterfly, inlet, stomach, and adjusting valve. The door instrumentation valve offers a full opening or closing of the gaps. they do not allow any misfortune of the liquid pressure factor. The connecting valve is generally called. a fast-acting valve because of its operation.

between the comforter and the valve, there is a stomach. later considered a stomach valve. that ensures that there is no contact between these parts. Most petrochemical companies use a valve due to its round bore and tiny size. It gives a situation close to the valve. Either because it can, when a full closed position is not needed, a globe valve is used. They are known for their seatless erosion ability. The circle and the seat do not have contact, so the erosion is absurd due to the entry of liquid.

The butterfly INSTRUMENTATION VALVE has a circle. whose width is equal to the distance between the valve body. Likewise, he stays away from the contact of the circle and the body. This ensures that there is no ground during opening and closing. The check valve prevents further progression of the liquid. The INSTRUMENTATION VALVE is normal in synthetic, pipeline, design. petrochemical, gas, and oil plants.

Instrumentation Valves Specification

Standards API600, BS1414, ASME B16.34

Face to face ANSI B16.10

End connection Raised face, ring joint, undrilled, butt weld ANSI B16.25, ANSI B16.5, ASME B16.47 Series An or B

Marking MSS-SP-25

3-way manifold valve for instrumentation in nickel alloys. Inconel, Incoloy. steel, Monel, etc. The offered 3-way manifold valve for instrumentation is created. using the preeminent nature of the hardware. Gautam Steel Proficient in Instrumentation Quality Assistance 3-Way Manifold Valve. Timely Transportation, and Customer-Centered Approach Backed by a group of professionals. we are busy offering a scope of exceptional 3-way Instrumentation Manifold Valve quality.

Instrumentation 3-way manifold valve specification

Kind:

3-way manifold valves

Work pressure:

6000 psi and better

Standard:

Planned and made to regulate API / BS / DIN STANDARD

Final connections:

¼ “and ½” Associations with BSP, NPT, BSPT

Organ seat:

Standard P.T.F.E

Maximum temperature:

– 20 degrees C to +230 degrees C are based on various materials

Material:

SS316, SS304, CS, Hastelloy. Monel then in

Activity:

Pneumatically controlled: smooth, easy, low torque, long life

Quality:

The best quality in visuals, materials, dimensional accuracy, operation, leak adjustment onwards

Application Industries:

Refineries, liquid petroleum gas preparation plants. petro-synthetic plants. structures difficult to cut due to strong substance dust, rust, earth and then in

Tests:

• Each valve is 100% tested to ensure leakage is tight on the housing, seat, and gland.

Reflexes:

• Our complex valves are made up of 1/2 “NPT (F) connections.

• Pipe-to-column or rib-to-rib pipe associations are provided.

• One balancing valve, two square valves, and one pair of 1/4 “NPT (F) flushing

• To deal with

About

We are one of the leading manufacturers of optimum quality Pipes & Pipe Fittings. Their high tensile strength, seamless finish and resistance to corrosion, make these pipes highly demanded.

Register Office

Contact

(+91) 9167472806

apexiametal@gmail.com

export.apexia@gmail.com

Follow

Copyright 2021 © Apexia Metal – All Rights Reserved || Developed & Maintained by Adsense Networks