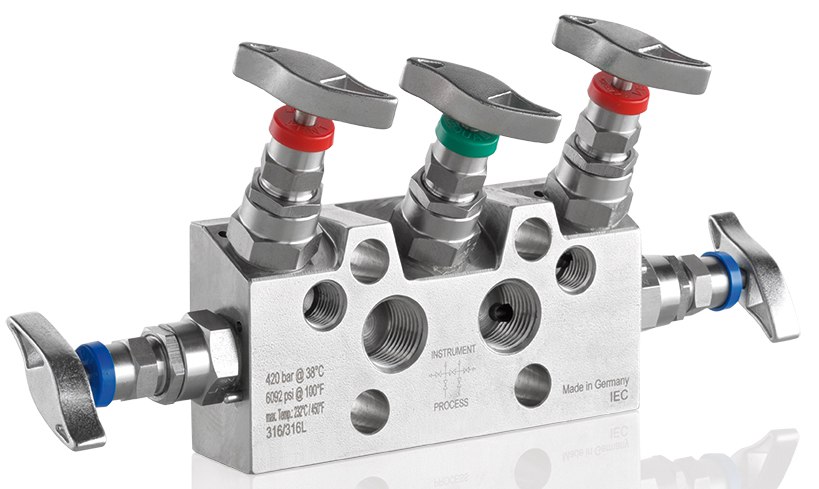

Stainless Steel 5 Way Manifold Valve

Stainless Steel 5 Way Manifold Valve Manufacture

The Apexia Metal Is Provide Regarded as valuable and huge, a chrome steel valve manifold ends up being useful in a wide range of uses. For example, the double block and. bleed manifold can be used in versatile small machines for heavy mechanical plants. By centering any liquid force structure. a 5-way manifold valve can further develop productivity. In addition, the pneumatic collector block can also help reduce energy costs. It is understood that a D03 manifold has expanded. energy productivity with more limited flow paths. thereby limiting pressure drop and heat.

2/3/5 way manifold valve

Size: 1/2 “to 4” (DN25-DN200)

Chain: NPT PT BSPP G

Association: Welded, Plug, Fixed, Flanged, Threaded

Pressure factor class: PN10 / 16

Complex Check Valve features a conservative meeting plan. clarifies your diminished size and weight. The qualities of the manifold valve are that they are leaking check, easy to calculate, long service life. The complex valve is employed for the setting frame. that directs the progression of the liquids with. an appropriate game plan of the opening and closing of the device.

India 5 Way Manifold Valve Manufacturers, Manifold Check Valve Exporter. Instrumentation Manifold Valve Distributor

Stainless Steel 5 Way Manifold Valve Manufacture in India

The manifold bleed valve has a maximum pressure factor of 6000 PSI. The instrumentation manifold valve has a special opening underneath to associate a line. We offer various kinds of manifold valve manufacturers high-quality electric. pneumatic and manual driven 2 way manifold valves. 3 way manifold valves and 5 way manifold valves. The 3-valve complex can be a contraption that ensures that the container will not run out. This valve also allows the transmitter to be disconnected from the cyclic circle. It consists of two square valves, for example. high-pressure factor and low-pressure factor block valve.

The Stainless Steel 5 Way Manifold Valveconsists of two square valves, 1 equalizer valve, and a pair of test valves. This 5-way complex valve is the most recognized complex valve for differential. pressure factor transmitter.

The use of stainless steel manifold valves in petrochemical plants, refineries, shipbuilding. water treatment plants. then we supply complex Stainless Steel 5 Way Manifold Valvewith the highest notch of tempered. steel materials for its durability and. extraordinary type in mechanical business. We are one of the complex valve manufacturers of driving pressure gauges. 3-type valve manifold, T-type manifold valve, and H-type manifold valve. steel manifold valve manufacturer.

Manifold valve manufacturer associates a minimum of two valves to a water-powered structure. These valves are used for a wide selection of uses directly. from portable appliances to substantial mechanical instruments. Steel manifold valves have proven to be more efficient and lower costs. These manifold valves operate up to 20,000 psi (1,379 bar) with a variety of end associations. These manifolds generally incorporate ball, needle, drain, and vent valves.

Request

Synthetics Industry

Fat and compost industry

Shipbuilding

Development industry

Key features

The 5-valve manifolds are intended for widespread or separate mounting.

Interface from the measurement side 1/2 “npt (f) and. the instrument side 1/2” npt (f) associating transmission lines and. transmitters with a basic arrangement of three valves. considers two simple obstacles or confinement. one Equalizer valve is called a static valve. pressing transmitting factor or check.

Drainage / ventilation association with s.s. Attachments will be delivered upon request.

Heat code detectability.

Cap assembly

Cap: victory verification located in the back.

Shaft: ground and coiled rope. Pressing under the rope.

Shaft Tip: Non-rotating tip lock type and delicate location.

Debris Cap – Dust Cap protects the stem strings. the detectability of the outside contaminant heat code.

Specialized specification

Size: 1/4 “and 1/2” and 3/4 “

Accessible custom size according to prerequisites

End connection: NPT, BSPT, BSP, and Socket Weld.

Working pressure: 6000 psi (413 bar)

Temperature Rating: PTFE 450 ° F (232 ° C) Grafoil 700 ° F (371 ° C “)

Discretionary acre gas management valves are accessible by claiming nace mr-01-75

Stem packing: PTFE, Grafoil.

Hole: ø4.7

Stainless Steel 5 Way Manifold Valve Supplier

All valves are 100% in-line tested.

Nickel:

Grade: nickel 200, nickel 201

Inconel:

Grade: Inconel 600, Inconel 601, Inconel 625, Inconel 718

Incoloy:

Grade: Incoloy 800, Inconel 800H, 800HT

Hastalloy:

Grade: Hastalloy B2, Hastalloy B3, Hastalloy C22, Hastalloy C276, Hastalloy X

Titanium:

Grade: Gr1, Gr2, Gr3, Gr5, Gr7, Gr11

Hardened steel:

Grade: ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304 / 304L, 304H, 316H, 316 / 316L. 321, 330, 347, 309 / S, 310 / S, 317 / L, 333, 410 / S, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404

Carbon Steel:

Grade: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 and WPHY 70, SA105

Duplex steel:

Grade: ASTM / ASME A / SA 182 UNS F44, F45, F51, F53, F55, F60, F61

Amalgam steel:

Stainless Steel 5 Way Manifold Valve Supplier in India

Grade: ASTM SA 182 – E25, E26, E27, E28, E29B, E30B, E39B, E40B, E36B, E36C, E41B, AISI4130, AISI4140, AISI4340. 42CRMO4, 16MNCR5, 20MNCR5, 21CrMoV57, EN35491, EN35411, EN359 , P22, P91, P9, P5, P92, EN42J, EN8, EN19

These complexes are often mounted directly to the transmitter. which has 54mm or 32mm connections for focusing. The channel is ½ “NPT F or flanged. Two separating valves and one equalizer valve are provided along with the 1/4” NPT channel F as an alternate. These valves are primarily used with Dp transmitters.

The 5-valve manifolds are designed for separate or distant mounting. Association from the measurement side 1/2 “NPT (F) and. the instrument side 1/2” NPT (F) Connection of motivation lines and transmitters. with a simple arrangement of five valves. that consider two simple to obstruct or isolate. two, a bleed valve or vent fitting a static pressure factor transmitter or control.

Drainage / ventilation association with s.s. Assembly will be done on request.

Inaccurate weight: xxx Kg (xxx Lbs.).

Heat code detectability

Treated Steel Manifold Valve Specification

Item Name: Manifold Valves / SS304 / 316L Manifold Valves

SS304 / 316L Manifold Valve Design: Forged Body with Inline / Straight or Angle Pattern. Integral Bonnet Design

Accessible SS304 / 316L Manifold Valves Size: 1/8 to 1 “, custom sizes accessible upon request

Connection thread, weld, or tube end

Flow pattern: straight / angle

Power: Manual

Work pressure:

Up to 6000 PSIG, manifold valve manufacturers are also accessible. which will affect higher pressure factor

Hardened Steel Manifold Valves – Up to 6000 psig (414 bar)

Steel Manifold Valves – Up to 3000 psig (207 bar)

Metal Manifold Valves – Up to 3000 psig (207 bar)

Test: 100% factory tested

Complex valve material: SS 316, SS 304, C.S, F11, Hastelloy, Monel 400

Stem: Vee Steam is standard for pressure adjustment even at elevated temperatures. Stem control and soft seat stem are discretionary

Temperature classification:

PTFE 450F, (232C) / Grafoil 700 F (371C)

PTFE packing: – 65 ° F to 450 ° F (- 54 ° C to 232 ° C)

Appearance packaging: – 65 ° F to 600 ° F (- 54 ° C to 315 ° C)

Packing: PTFE, Grafoil, PEEK / PCTFE

End connection: male and female NPT, BSPT, socket weld tube connections. (SW) or double ferrule, male to female. female to female

Test and Inspection: Manufacturer’s Test Certificate consistent with EN 10204 / 3.1. Raw Material Certificate, Third Party Inspection, Buyer’s Inspection

The 5-way manifold valve can be a universally useful instrument. complex intended to associate differential pressure factor transmitters. or flow registers to the motivation line tubing. Associations are 1/2 ″ NPT on industry-standard 3-2 / 8 ″ focus-to-focus measurements. (models for 2-3 / 16 ″ and 2-1 / 4 ″ focus-to-focus measurements also are accessible). 5 valve complex (double isolation, equalization, double vent). for a prudent method of mounting differential pressure factor transmitters.

The 5-way manifold valve is designed for remote mounting on instruments. that use stringed instruments and interacting associations. These complex valves have two release valves. one balancer and two-channel / alignment valves. the quality cycle and instrument associations are ½ “NPT F and. therefore the channel associations are ¼” NPT F. Blanking plugs are provided. The instrument associations are 54mm apart. but can also be used for other focus distances with the help of screw-in accessories.

About

We are one of the leading manufacturers of optimum quality Pipes & Pipe Fittings. Their high tensile strength, seamless finish and resistance to corrosion, make these pipes highly demanded.

Register Office

Contact

(+91) 9167472806

apexiametal@gmail.com

export.apexia@gmail.com

Follow

Copyright 2021 © Apexia Metal – All Rights Reserved || Developed & Maintained by Adsense Networks