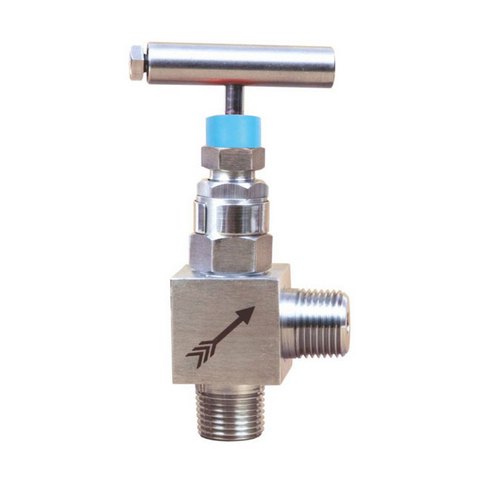

Stainless Steel Angle Type Needle Valve

Stainless Steel Angle Type Needle Valve Manufacture

The Apexia Metal Is Provide SS 304 Needle Valve and Needle Management Valve Supplier

producer and supplier of various forms of valves, for example, SS 304 needle valve. The needle valve works with a needle that closes the road with precision and maximum comfort. Grade 304 needle valves are solid and. safe against erosion, however, the SS316 needle valve is safe for consumption.

The application can be found within the oil and gas business. energy era, composites, and organics. Urgent issues limit the various types. for example, the CF8M stainless steel angle needle valve will operate up to 10,000 psi or 689 bar. Valve operating temperatures range up to 648 degrees Celsius. Also, applications will be found in meters and instruments for precision estimations. CF8 stainless steel flanged needle valves come in sizes.

The final association will go from 1/8 creep to ½ inch. tip associations for the various types, such as the ASTM A351 CF8M 316 1/4 in. needle management valve. will work as duolok, unilok, griplok types, tube fittings, or trufit pipe fittings. As the main supplier, we tend to offer numerous types, for example, A351 CF8 304 et al. Water flow management needle valve.

SS 304 Needle Valve Producer

A stainless steel compression needle valve could be a type of valve designed with a contact port and. plunger configured in the shape of a needle. The needle valve gets its name from the needle-shaped plunger. An advantage of the 1/2-inch stainless steel needle valve. It is that it authorizes the actual flow pattern. however, the 1/4 stainless steel needle valve is simply ready to test and. achieve moderately low flow rates. Current can be controlled and delivered by the Ss-1rs4 needle valve using a spindle.

Stainless Steel Angle Type Needle Valve Manufacture in India

Stainless Steel Angle Type Needle Valve incorporates a similar very small orifice with a tight seat for quite some time. In addition, the Ss-1rs6 needle valve also incorporates a molded plunger. with needle towards the end of a screw. The plunger is used inside the stainless steel integral. bonnet needle valve fits exactly to the seat. A flexible and celebrated compound, the stainless steel needle valve. depending on the grade used can provide fantastic direct erosion opposing properties.

Most needle valve manufacturers expressly recommend it. because the SS316 needle valve was used. in food and beverage, handling is not easily consumed. with the artificial compounds present in food. It is difficult to recognize if the hydraulic needle valve is stopped or open, unlike ball valves.

Instrumentation Stainless steel needle valve

Treated Steel Female Thread Needle Valve / Integral Bonnet Needle Valve

Hardened Steel High Gauge Needle Valve

6000PSI Hardened Steel Female Integral Thread Solid Needle Valve

High-pressure stainless steel needle valve

Hardened Steel Bar Needle Valve

High-Pressure Swagelok Type Hardened Steel Needle Valve

1000WOG Rib Ends of 304 2PC Hardened Steel Floating Valve

Stainless Steel Needle Valve with Npt Thread

Angle Flow Management Valve / L-Type Hardened Steel

6000psi 1/2 Npt 316 Stainless Steel Female Thread Needle Valve

High vacuum coolant intentional body 1/2 1/4 in female metal Npt ss316 needle valve

Hardened Steel Hydraulic Needle Valve

Stainless Steel Angle Type Needle Valve Supplier

Male-female BSP Thread hardened steel 304 1/4 needle valve pn63

SS316L 1/2 “NPT female male thread 10000PSI Needle valve for oil and gas

Mild steel High-pressure problem Fluid gas needle valve

Pressure Stainless Steel Needle Valve

SS304 SS316 female configuration needle valve

Straight needle valve with nozzle Threaded cap Double nozzle Tube ends

Swagelok type ten thousand 6000 Psi 1/2 1/4 in. Female NPT SS316 Needle Valve

Hardened Steel Flow Management Needle Valves

3000 psi Stainless Steel Water Hydraulic Needle Valve

3/4-inch 316 stainless steel general hydraulic management needle valves

J23W-160P SS304 High-Pressure Welded Needle Valve

Hardened Steel Needle Valve Specification

Item Name Needle Valves / Diaphragm Needle Valve SS316

Hardened steel needle valve design Forged body with in-line/straight or angle pattern. integral bonnet style

Accessible size from SS316 needle valve manufacturers. from 1/8 to 1 “, custom sizes accessible upon request

Power manual

Straight / Angle Flow Pattern

Male and female end connection NPT, BSPT. Socket Weld (SW) or Double nipple tube connections, male to female, female to female

Work pressure

Up to 6000 PSIG, needle valve size can also be accessed, which will modify the upper-pressure problem

Hardened Steel Needle Valves – Up to 6000 psig (414 bar)

Steel Needle Valves: up to 3000 psig (207 bar)

Metal Needle Valves: up to 3000 psig (207 bar)

Pipe connection, welding, or finishing thread

Temperature rating

PTFE 450F, (232C) / Grafoil 700 F (371C)

PTFE packing: – sixty-five ° F to 450 ° F (- fifty-four ° C to 232 ° C)

Appearance packaging: – sixty-five ° F to 600 ° F (- fifty-four ° C to 315 ° C)

Needle valve material SS 316, SS 304, C.S, F11, Hastelloy, Monel 400

Stem Vee Steam is common for pressure comfort even at elevated temperatures. Stem Handling and Soft Seat Stem Discretionary Square Measure

Stainless Steel Angle Type Needle Valve Supplier in India

PTFE, Grafoil, PEEK / PCTFE packing

100% tested plant tested

Manufacturers of specific needle valves

Bolted Ends of Essential Bonnet

Essential Bonnet Double Nozzle Ends

Bonnet Style Screwed Female Ends

Male x Female Bonnet Style Threaded Ends

Bolted Bonnet Style Double Nozzle Tube Ends

Pointed Needle Valves – Bolt-On Bonnet Style

Shading Flow Needle Valve

Shading Flow Management Valve

Connecting Valves – Bolted Bonnet Style Male / Female Ends

Test and Inspection Manufacturer’s Verification Certificate per Nut 10204 / 3.1. Raw Material Certificate, Third Party Examination, Buyer Examination

Standard needle valve options measure square based on the following:

High-pressure rating offered up to 15000 notation,Stainless Steel Angle Type Needle Valve

Accessible in a variety of fabrics

Residue Cap gave

Assortment of finishing associations incorporates male / female NPT, BSPT, BSPP

Smaller arrangement

Every check valve is plant tested

Low operating torques

Common high-pressure needle valve

Test and examination according to API 6D / API 598

Planning and manufacturing according to BS 1868

Pressing subject and temperature according to ASME B16.34

Eye to eye according to ASME B16.10

Visual examination according to MSS SP-55

Spine dimensions according to ASME B16.5

Sealed to: MSS SP-25

Detailed chart of needle valves

sizes 1/4 “to 1” (female / female BSP and BSPT), 3/8 “to 1” (female / female NPT) and 1/4 “to 1/2” (male / female BSPP).

Temperature range: -20 ° C to 230 ° C.

Operator bar, worked by hand.

Urgent emission rating: 6000 PSI.

What is a needle valve?

Custom valves were delivered obsessed with the need for applications. Tiny brass needle valves are accessible for lower application conditions. eg fuel infusion structures using smaller calculable needle valves than traditional ones. The limits of the urgent problem of needle valves squared on different types of valves. in the lightweight of the lowest data size and performance onboard types of filled bodies.

About

We are one of the leading manufacturers of optimum quality Pipes & Pipe Fittings. Their high tensile strength, seamless finish and resistance to corrosion, make these pipes highly demanded.

Register Office

Contact

(+91) 9167472806

apexiametal@gmail.com

export.apexia@gmail.com

Follow

Copyright 2021 © Apexia Metal – All Rights Reserved || Developed & Maintained by Adsense Networks