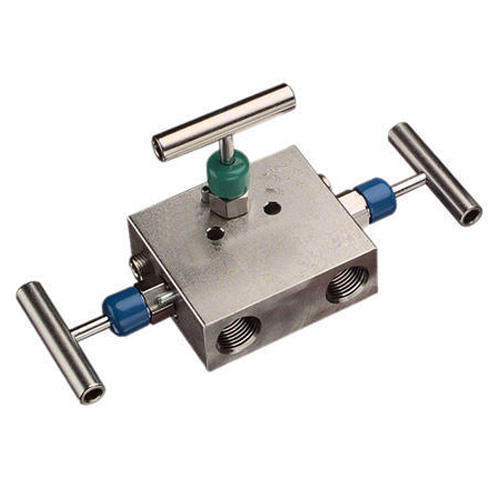

Stainless Steel Manifold Valve

Stainless Steel Manifold Valve Manufacture

The Apexia Metal Is Provide Treated Steel Valve Manifold, SS 5 Way Manifold Valve Suppliers. SS 2 Way Manifold Valve, Stainless Steel 3 Way Manifold Valves. Stainless Steel Instrument Manifold Valve Manufacturers

Hardened Steel 2 Valve Manifold, Stainless Steel Bellows Sealed Manifolds. Stainless Steel 5 Valve Manifold, Stainless Steel 3 Valve Manifold. Stainless Steel Valve Manifold Exporters. Stainless Steel Direct Mount Manifolds, supplier stainless steel remote mount manifold

The assembly of stainless steel complex valves is done. using the prevailing nature of the compound and current innovation. We are planning and. creating the item in keeping with the raw material quality guidelines and. by established creation standards, the company found.

On the creation floor, the expert master group is hired and is assigned. the job of taking a look at the feasibility of the creative interaction. Subsequently, we are directing workers to create the prevailing nature of valves. that ensure dimensional accuracy and smooth edges.

This item can be a combination of several great properties. that are making it a perfect choice for various purposes. Minimized plan, dust cap, up to 15000 ps, the high-pressure rating is accessible. low duty forces, each valve is tested. accessible in various materials and a variety of seal associations such as BSPP, male. NPT, lo feminine is accessible and opposition to consumption then properties are advertised.

Stainless Steel Manifold Valve Manufacture in India

Treated Steel Manifold Valve Grades

304 Hardened Steel Manifold Valves

304L Hardened Steel Manifold Valves

304H Hardened Steel Manifold Valves

Hardened Steel 310 / 310S Manifold Valves

316 Hardened Steel Manifold Valves

316L Hardened Steel Manifold Valves

316H Hardened Steel Manifold Valves

316Ti Hardened Steel Manifold Valves

317 / 317L Hardened Steel Manifold Valves

321 / 321H Treated Steel Manifold Valves

347 / 347H Hardened Steel Manifold Valves

904L Treated Steel Manifold Valves

SS collectors are regularly found in modern automotive and semiconductor applications. Collectors made of stainless steel can withstand a high-pressure factor and temperature. are incredibly strong and offer great protection against erosion. SS manifolds are accessible in remade sizes and shapes.

Collectors are often brought together in various applications. SS manifolds have active development. that will be welded into various pipe segments. Low-profile stainless steel manifolds are generally more practical alternatives. that are used in various companies around the world.

The attributes and qualities found within the collectors are exceptionally unmatched. and are used in various applications. Qualities such as great resilience and adaptability in heat applications. great protection against consumption, fully released sealing, and brilliant strength and toughness.

The manifolds have the necessary mounting sections. that are attached at the latches to provide stability. Stainless steel grade manifolds are accessible in tight sizes. and shapes that can fit into controllers and flowmeters.

Types of stainless steel manifolds

Required hood manifolds

SS Threaded Bonnet Manifolds

Hardened steel forged body manifolds

Hardened steel high-pressure manifolds

Non-rotating Stem Manifolds SS

Hardened Steel PFA Manifolds

Hardened steel manifolds

SS Locked Bonnet Manifolds

Stainless Steel Bottom Packing Manifolds

SS high-pressure manifolds

Manifolds (IPT Series)

Stainless Steel Manifold Valves

Straight collectors SS

SS collectors

SS Locked Bonnet Manifolds

Stainless Steel Bottom Packing Manifolds

SS high-pressure manifolds

Stainless Steel Manifold Valve Supplier

The reason for the impede and drain complex is to disengage. or obstruct the progression of the liquid within the frame. therefore the liquid upstream of the complex does not reach the different parts of the frame. that are downstream. Then, at that time, these chrome steel manifold valves drain. or vent excess liquid from the structure on the downstream side of the complex.

For example, an obstruction and drainage complex would be used. to prevent the progression of fluids to some segments. then, at that time, vent the fluid from the complex side of that segment.

Carbon Steel Manifold Valves is a nitrogen-tested assembly line. for spillage on the seat and press. performed with deionized water at 1.5 times the operating press factor. however, different tests such as vibrations, temperatures, helium, etc. are accessible on demand. Each package is known as proper and simple identification.

ANSI / ASME B16.10 Manifold Valve Types

Hardened Steel Manifold Valve Manufacturer

Steel Manifold Valve Supplier

Amalgam Steel Manifold Valves Exporter

High-pressure manifold valves

Steel Manifold Valves

Carbon steel manifold valves

Metal Manifold Valves

Nickel Alloy Manifold Valves

Duplex Steel Manifold Valves

Inconel Manifold Valves

Hastelloy Manifold Valves

Low-Temperature Steel Manifold Valves

Martensitic steel manifold valves

Austenitic stainless steel manifold valves

Duplex Stainless Steel Manifold Valve

High duplex stainless steel manifold valve

Nickel Aluminum Bronze Manifold Valve

Titanium steel manifold valves

Stainless Steel Manifold Valve Supplier in India

Manifold valve types:

Straight type

Integral T-type design with single flange

Type H design

Essential assembly

Distant mount

Ventilated base

Mounted independently

Highlight:

Mounting the Differential Pressure Factor Transmitter

Pressure factor measurement setup

Steam purge lines

Cycle instrumentation

304 mild steel multiport gauge valves cannot be hardened during heat treatment. however small parts are often solidified by cold working. This single-block, bleed-gauge. 304 stainless steel valves also perform slightly better in vigorously oxidizing. airs up to 816 degrees Celsius.

The 304 hardened steel two-valve manifold remote mount valves are counter-positioned. to the chromium carbide frame by adding tantalum and columbium. Meanwhile, since tantalum and columbium in 304 chrome steel three-valve manifold remote. mount valves have more solid proximity for carbon than for chromium. these tantalum-columbium carbides are accelerated within the grains. instead of creating on the grain boundaries. The 304 treated steel three-valve busbar type direct mount valves can also be used. in tough fluoride- or chloride-free configurations at controlled temperatures.

Details

Association: 1/2 “female NPT to 1/2” female NPT

Development of the body of a high resistance piece. for well-being without the need for welding.

The stems include a non-pivoting top with a delicate, effectively replaceable insert.

The lid locking pin prevents inadvertent disassembly of the valve.

316 treated steel developments for unmatched erosion clogging.

Cap-to-body seals are metal-to-metal, without using o-rings.

The mounting openings were adapted for self-supporting applications.

100% pressure factor tested for closure and minimum seals.

The collectors include a 4: 1 factor of safety.

Standard applicable to complex valves

Planning and manufacturing as indicated by: BS 1868

Regarding: ASME B16.10

Rib dimensions as indicated by: ASME B16.5

Pressure and temperature factor according to ASME B16.34

Test and inspection according to API 6D / API 598

Visual inspection according to MSS SP-55

Sealed as indicated by: MSS SP-25

About

We are one of the leading manufacturers of optimum quality Pipes & Pipe Fittings. Their high tensile strength, seamless finish and resistance to corrosion, make these pipes highly demanded.

Register Office

Contact

(+91) 9167472806

apexiametal@gmail.com

export.apexia@gmail.com

Follow

Copyright 2021 © Apexia Metal – All Rights Reserved || Developed & Maintained by Adsense Networks